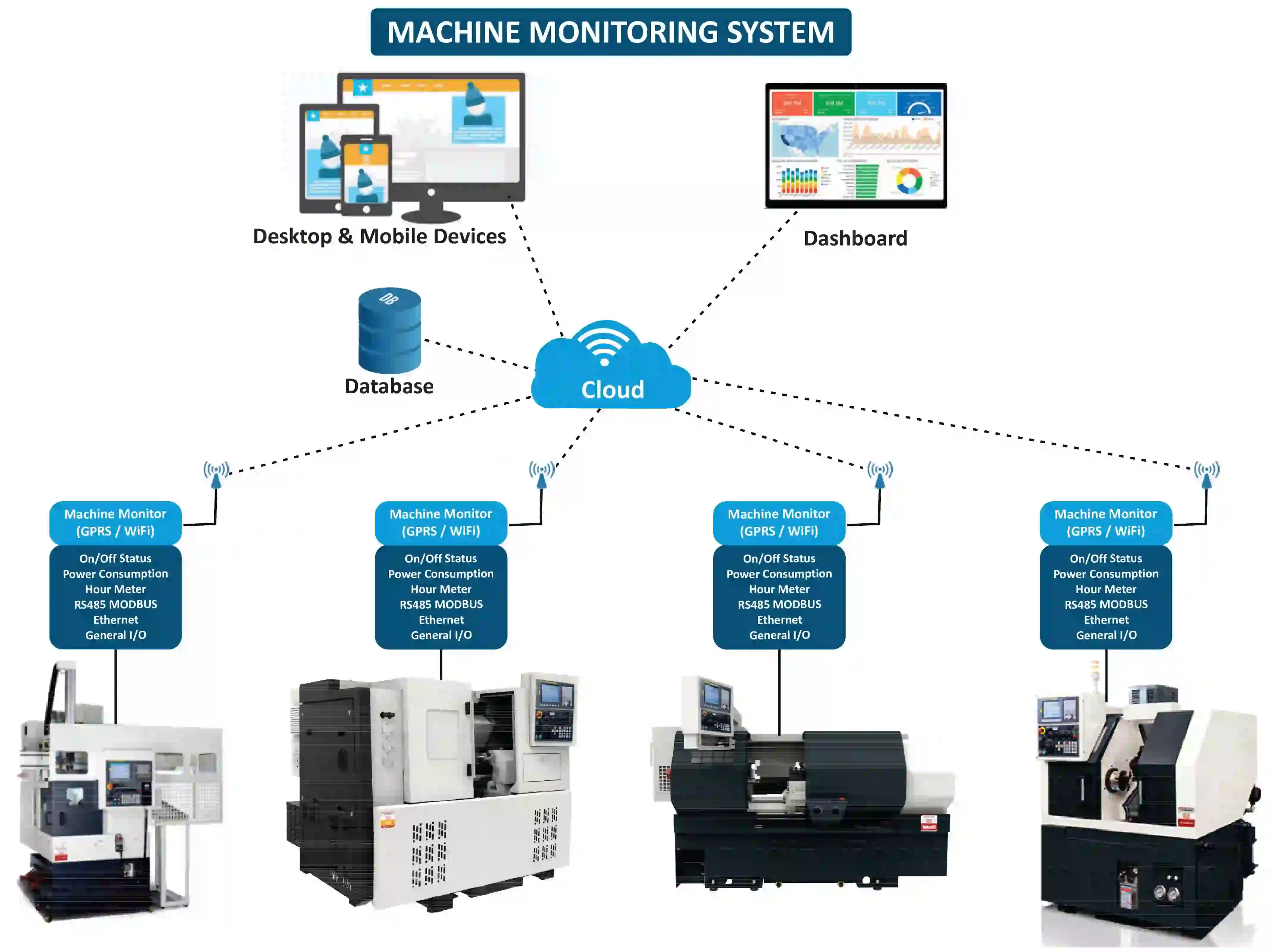

MACHINE MONITORING

EXECUTIVE SUMMARY

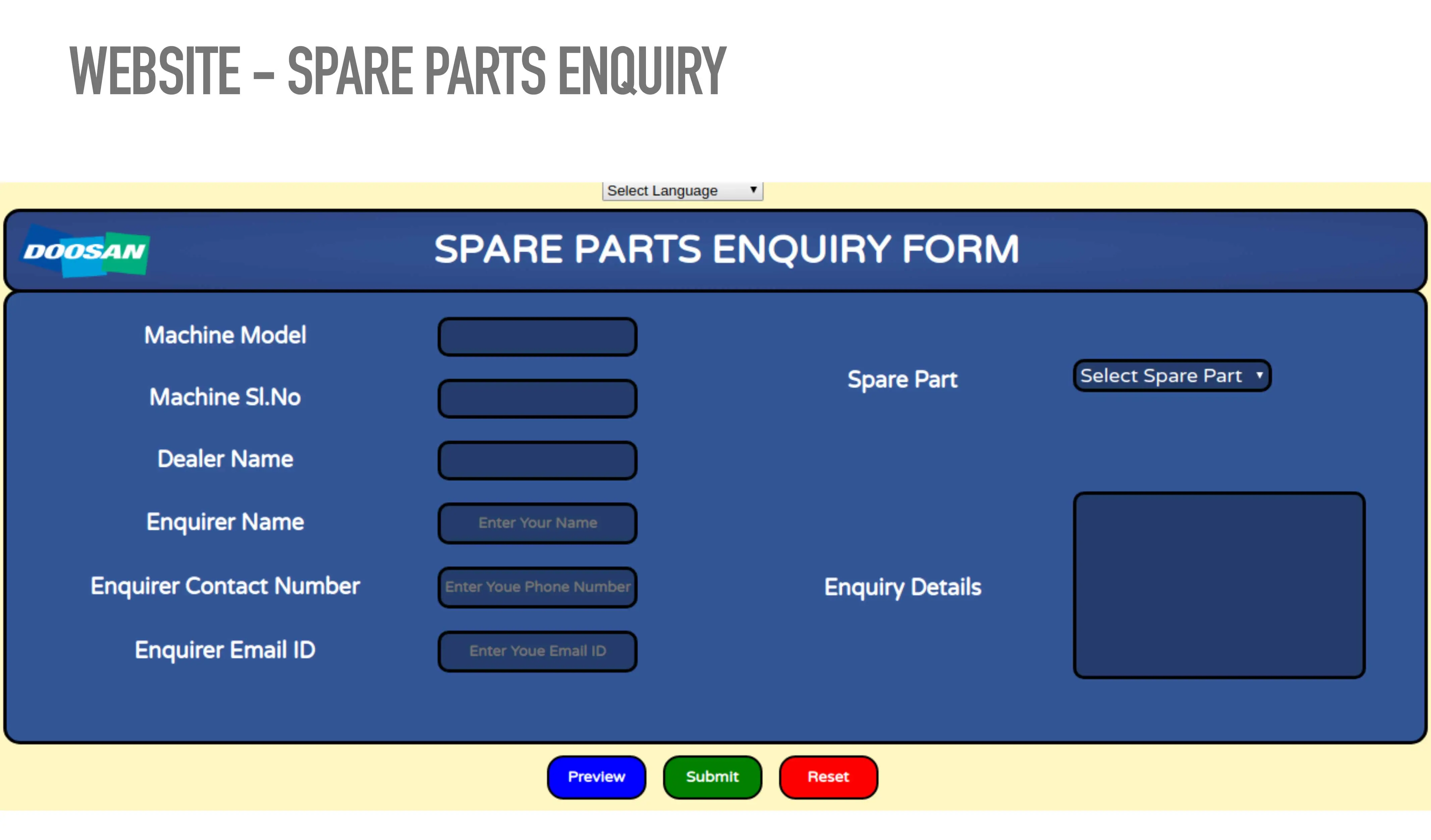

- Machine Monitor Hardware and Web Portal Software Suite to help customer

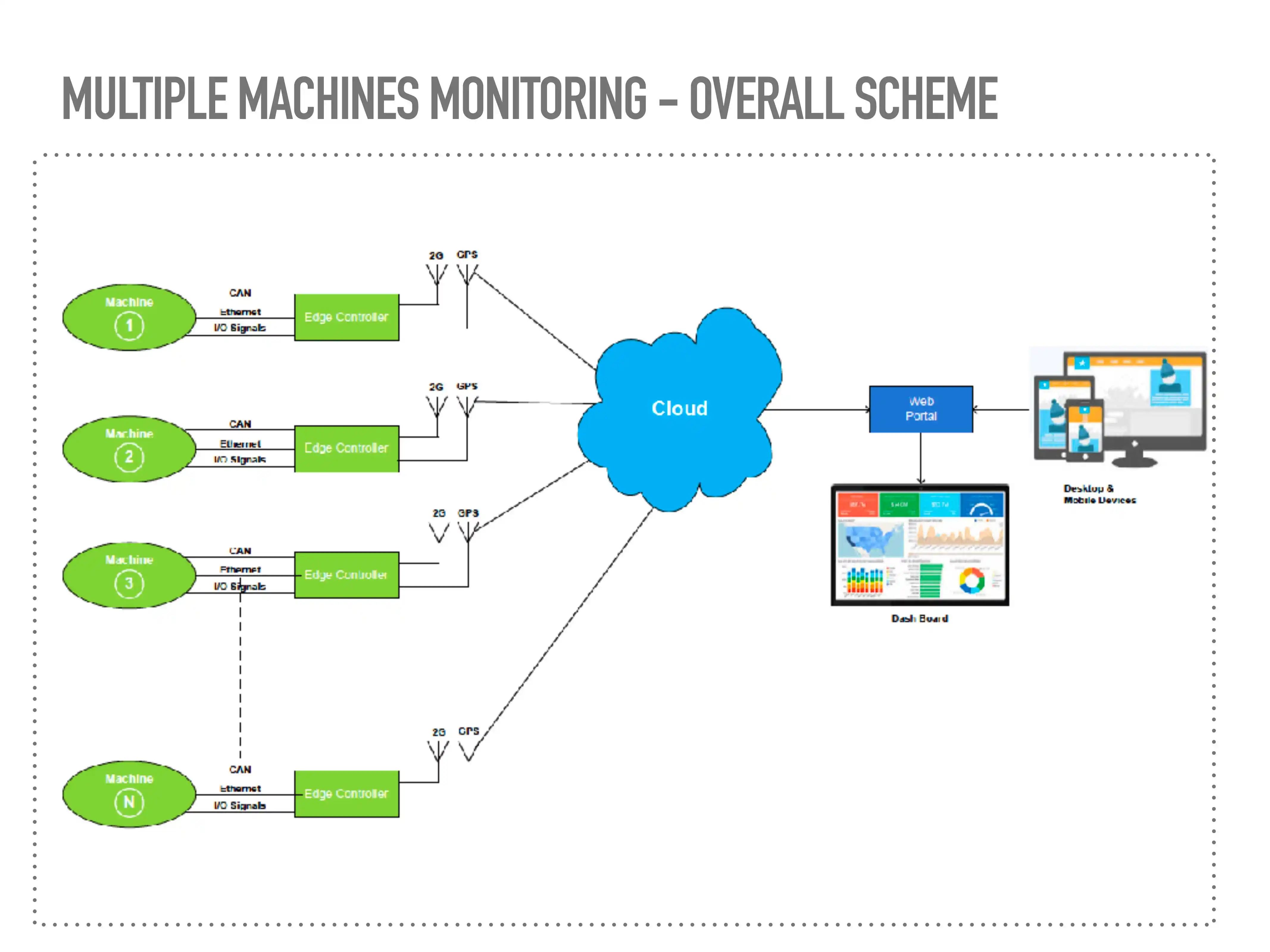

- Configurable, Multifunction, GPS enabled, Remote Monitoring controller with Cloud Connectivity

- In-built Telematics with 2G Modem and GPS

- Special Purpose Analog and Digital I/Os with Machine Communication Ports

- Ethernet Port / RS485 MODBUS to Connect PLCs

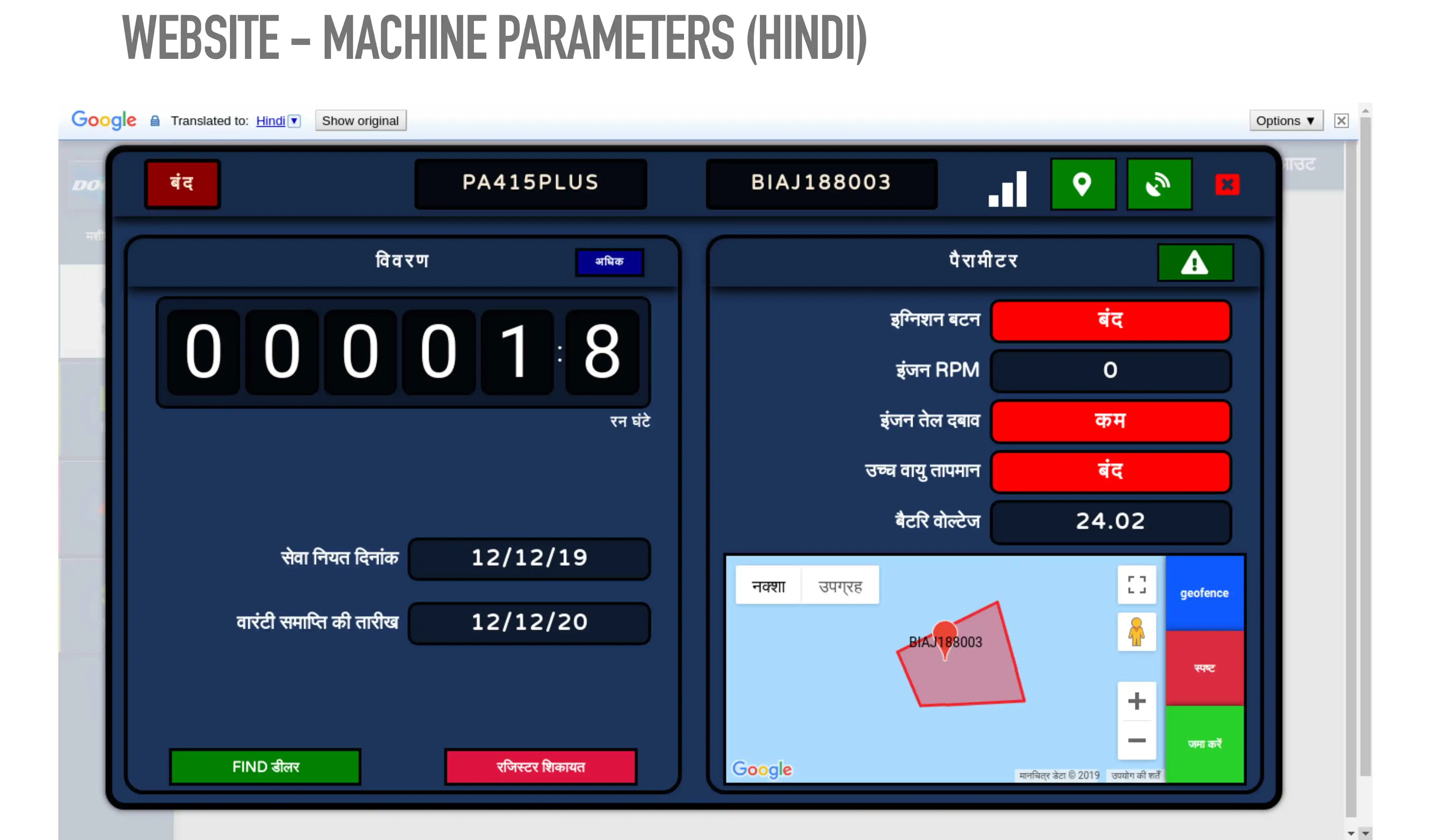

- Cloud-based Dashboard with Configurable Web Portal

- Machine owners can reduce costs, prevent downtime and optimize efficiency with intelligent analytics, real-time alerts and warnings directly from their computer or mobile device with an easy-to-use web portal.

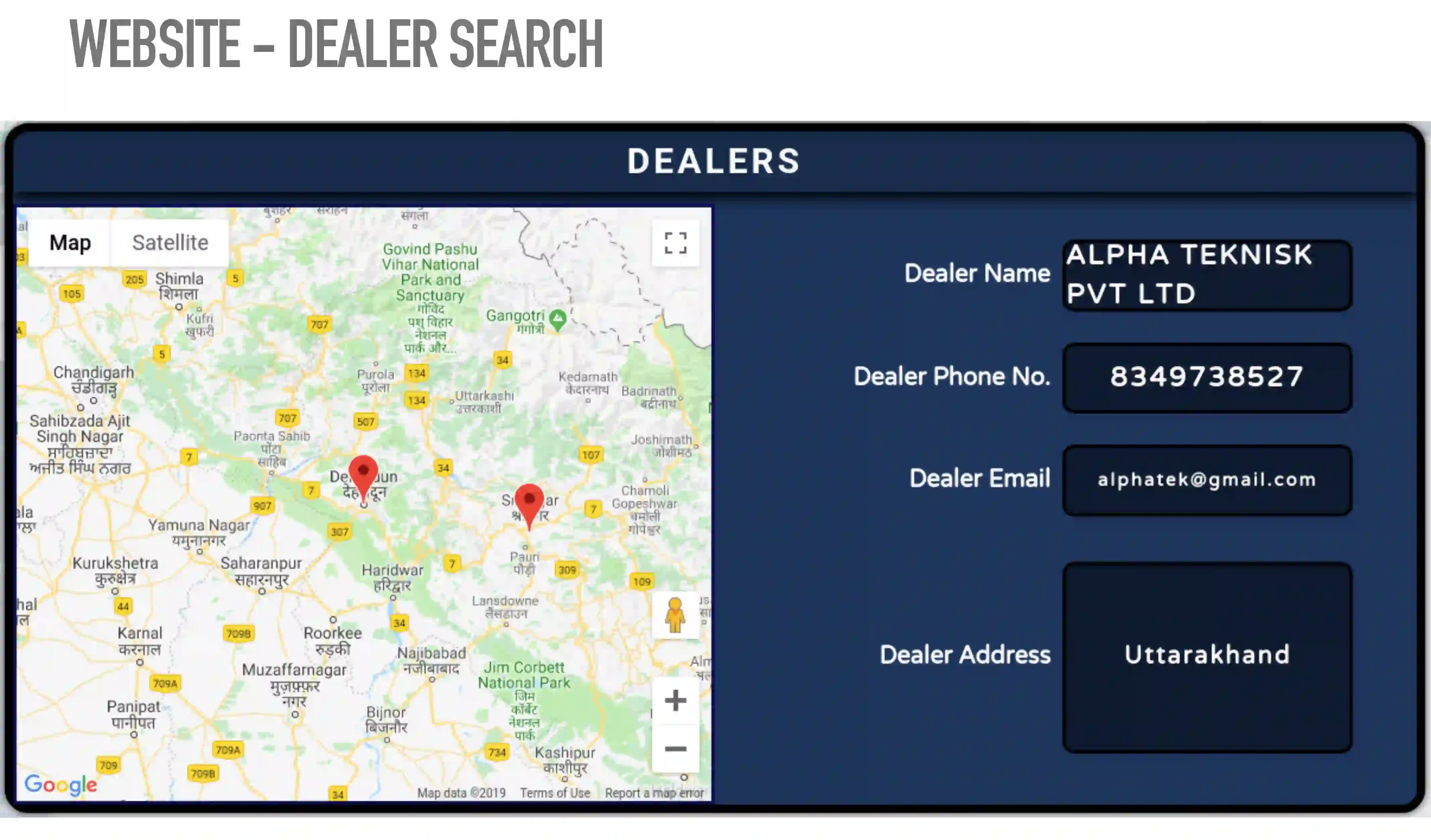

- Google Map Integrated Location Tracking for moving applications

- Compatible to all major manufacturers’ ECUs with J1939 Protocol

- Machine Health Monitoring through I/Os, Location Tracking with Hourly Usage Monitoring

- Data logging when there is no GSM signal with Time

- 3 LEDs to Indicate GSM Signal Level and 3 LEDs to Indicate Internal Battery Level (Future)

- Water and Dust-proof ABS Enclosure

CASE STUDY

- Leading Manufacturer of Borewell Compressors

- Buys and Uses Engines from Multiple Manufacturers

- Addressing Multiple Market Segments with different Capacity Engines

- Uses both Mechanical and Electronic Engines

- Measures directly from the engine sensors and calculates the various parameters

- Also acquires data from the CAN Bus if Electronic Engine

- Determines the Engine Location with the built-in GPS

- Transfers the data to Cloud through the Built-in 2G GSM Modem

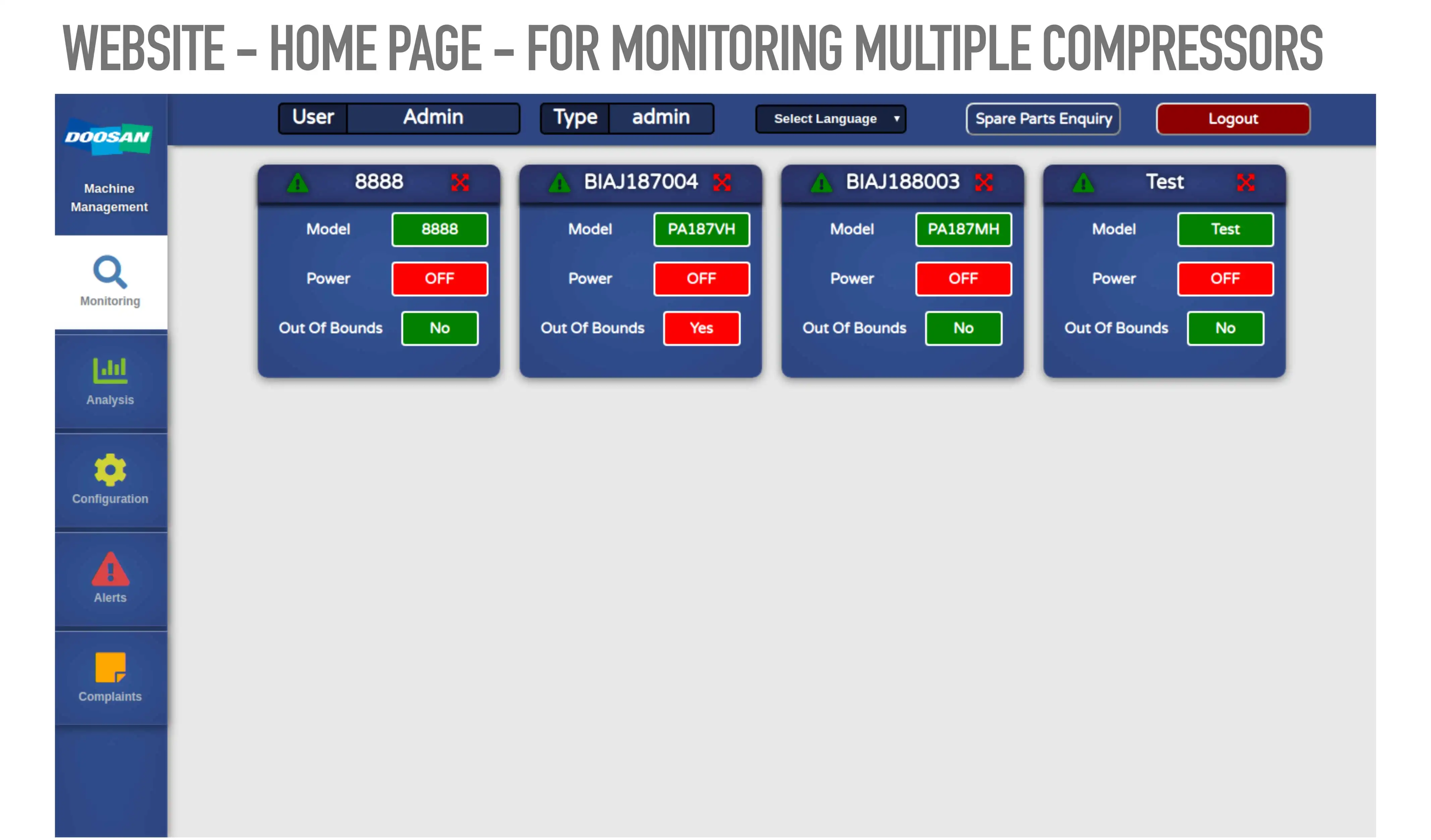

- Front End Web Based Dash Board Displays all the parameters

- Historical Data Analysis when needed

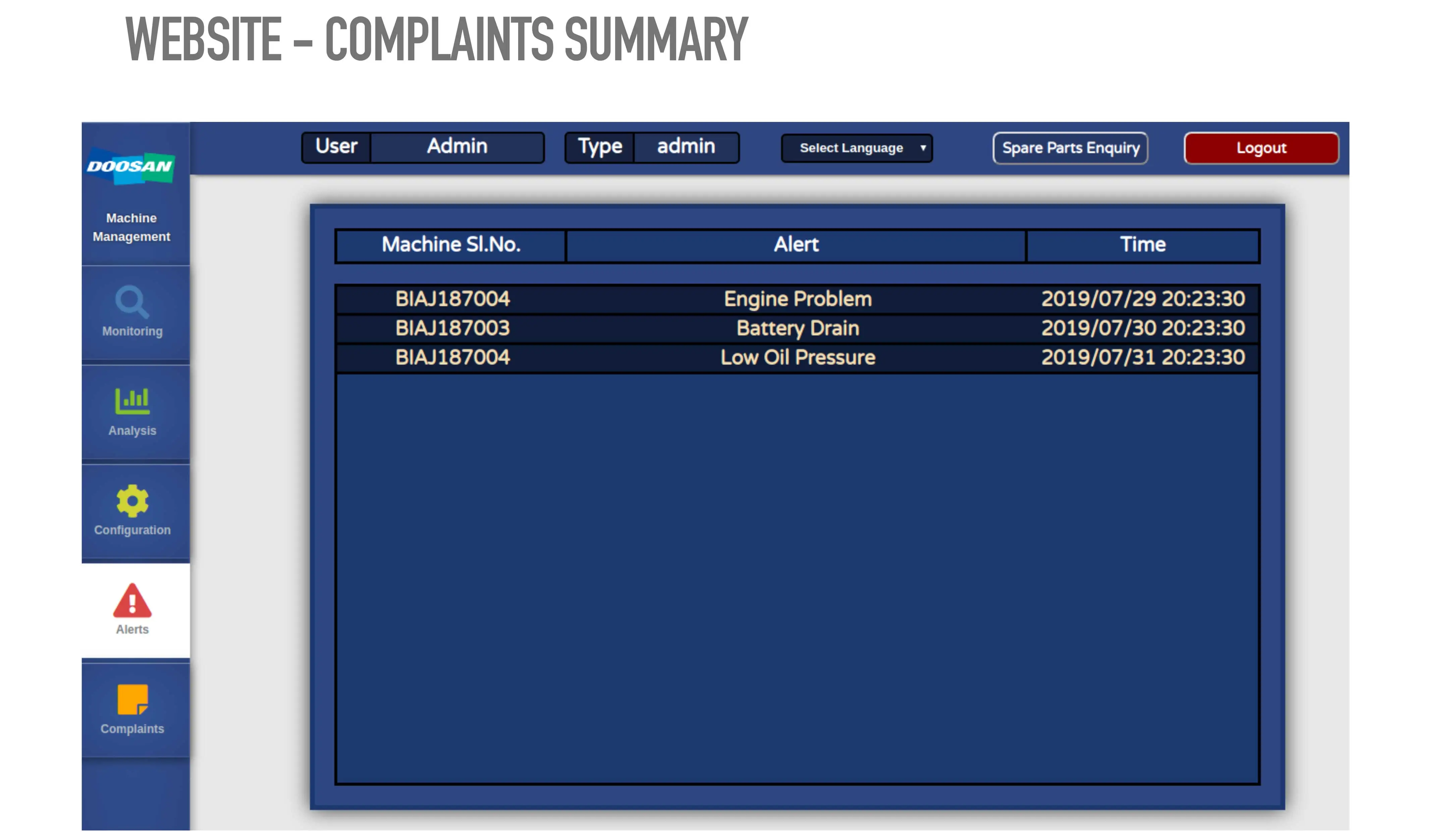

- Email and SMS Alerts to Owners, Dealers and Headquarters

DEEP DRILLING COMPRESSOR AND ENGINE MONITOR

PRODUCT DESCRIPTION

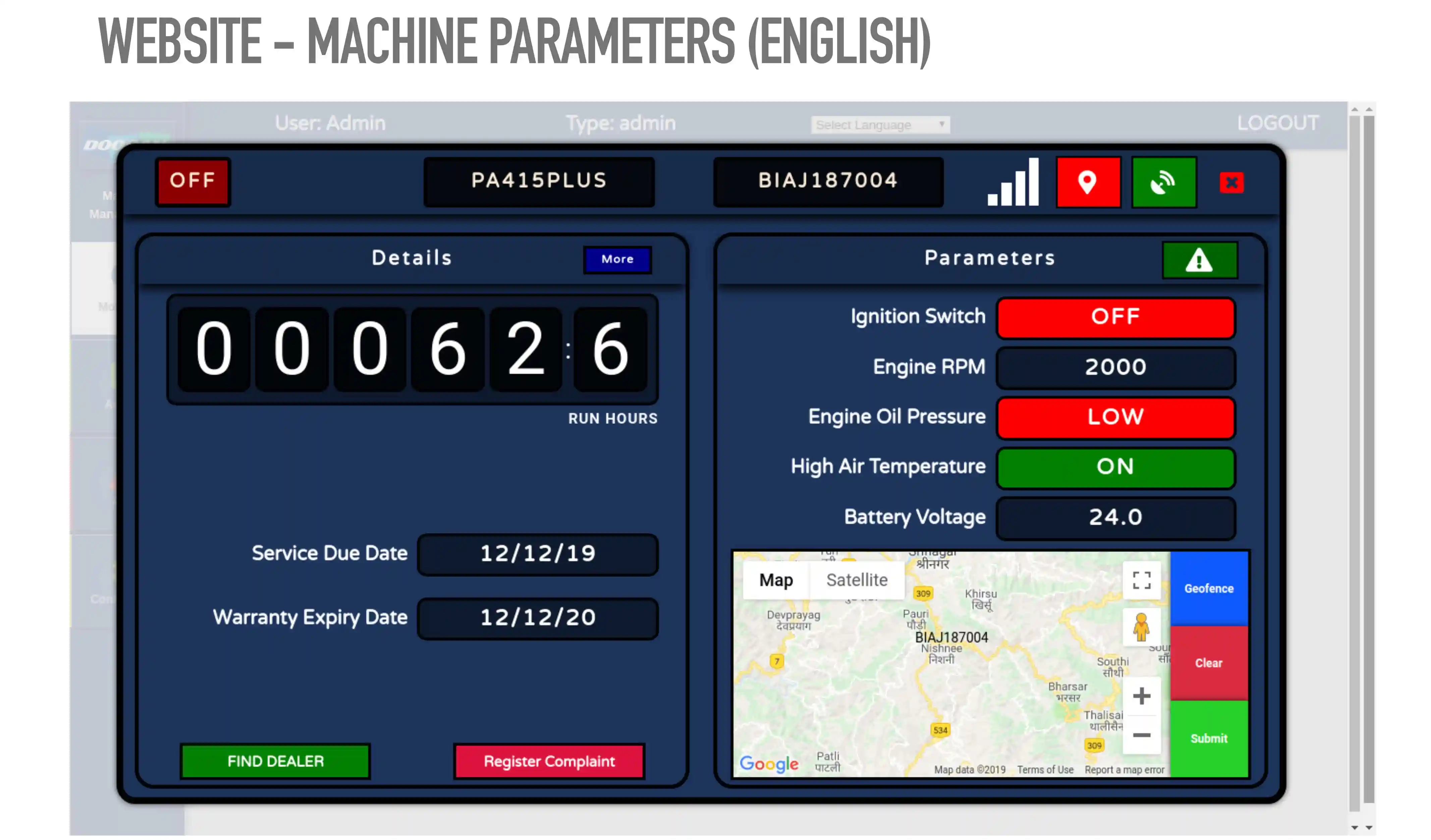

REMOTE MONITORING DASHBOARD

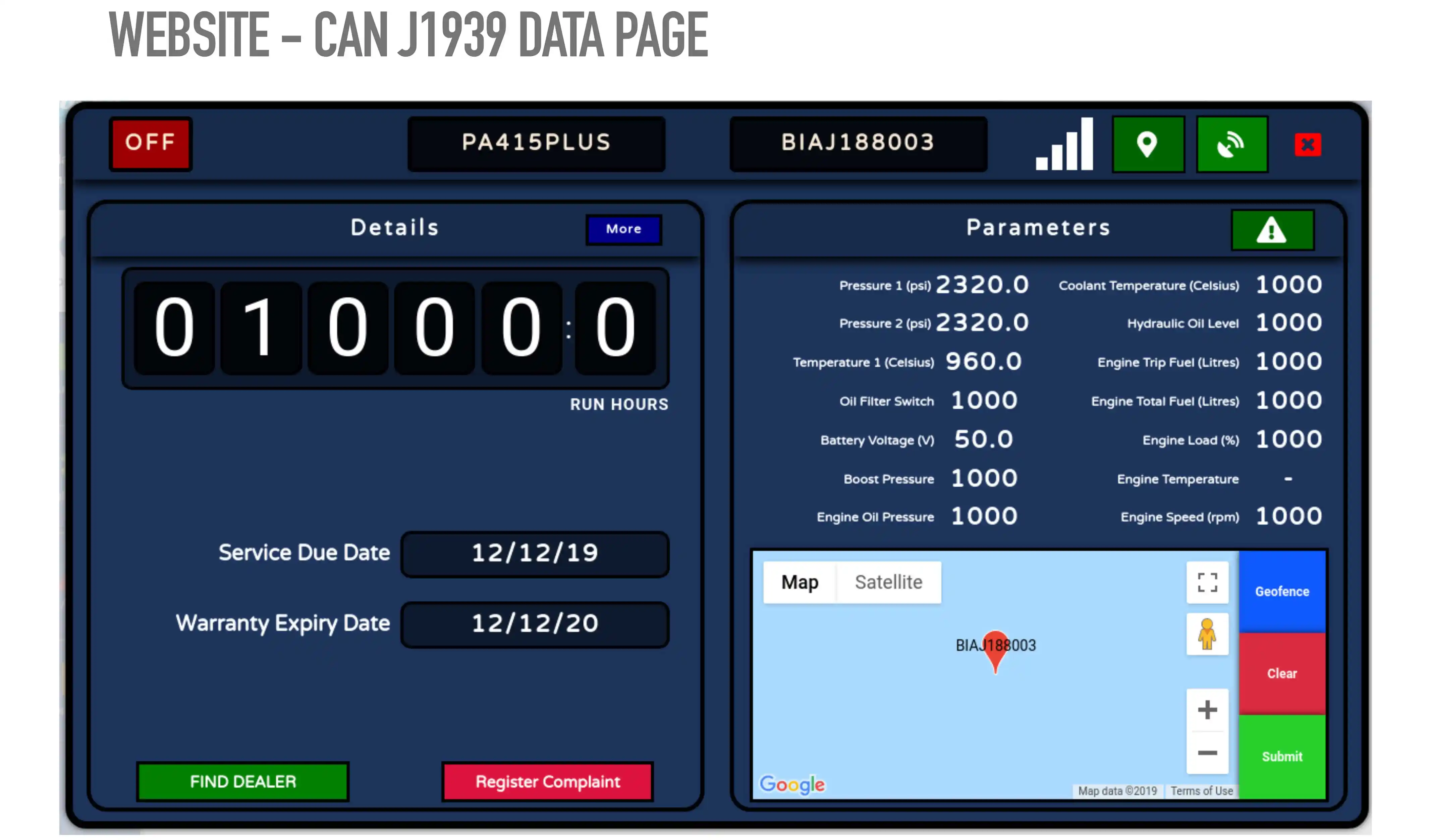

- Compressor ON & OFF Status

- Compressor Run Hours - Calculated by Authenticating Ignition Switch, Machine RPM together

- Machine RPM Display

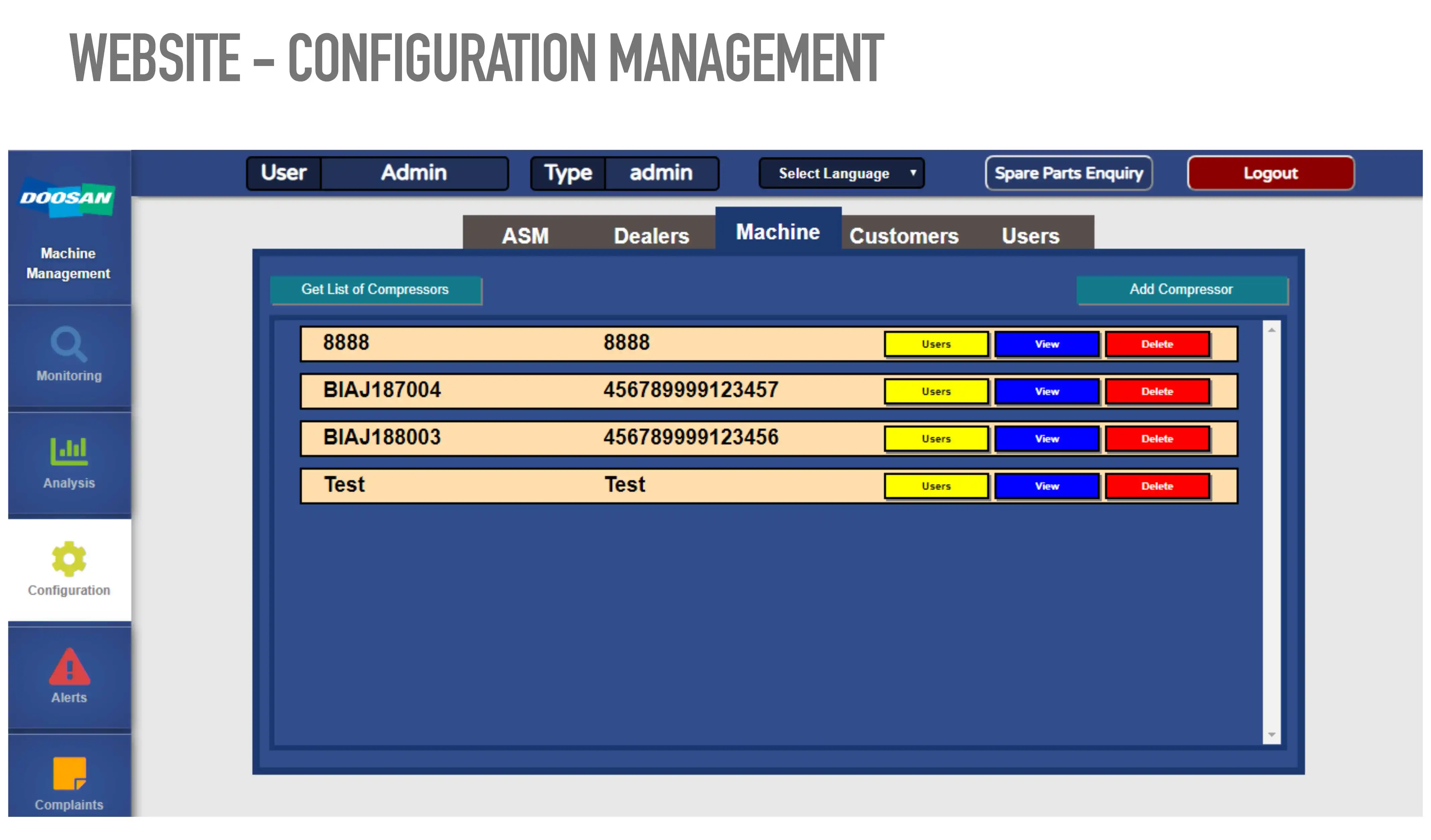

- Compressor Model No and Machine Serial Number Entry for Compressor ownership and location tracking

- Date and Time Stamp for all parameters

- Visualisation - Historical Graph Plotting of Critical Parameters (Under Development)

- Compressor service status reminders and warranty expiry reminders based on Compressor Hour Meter Reading

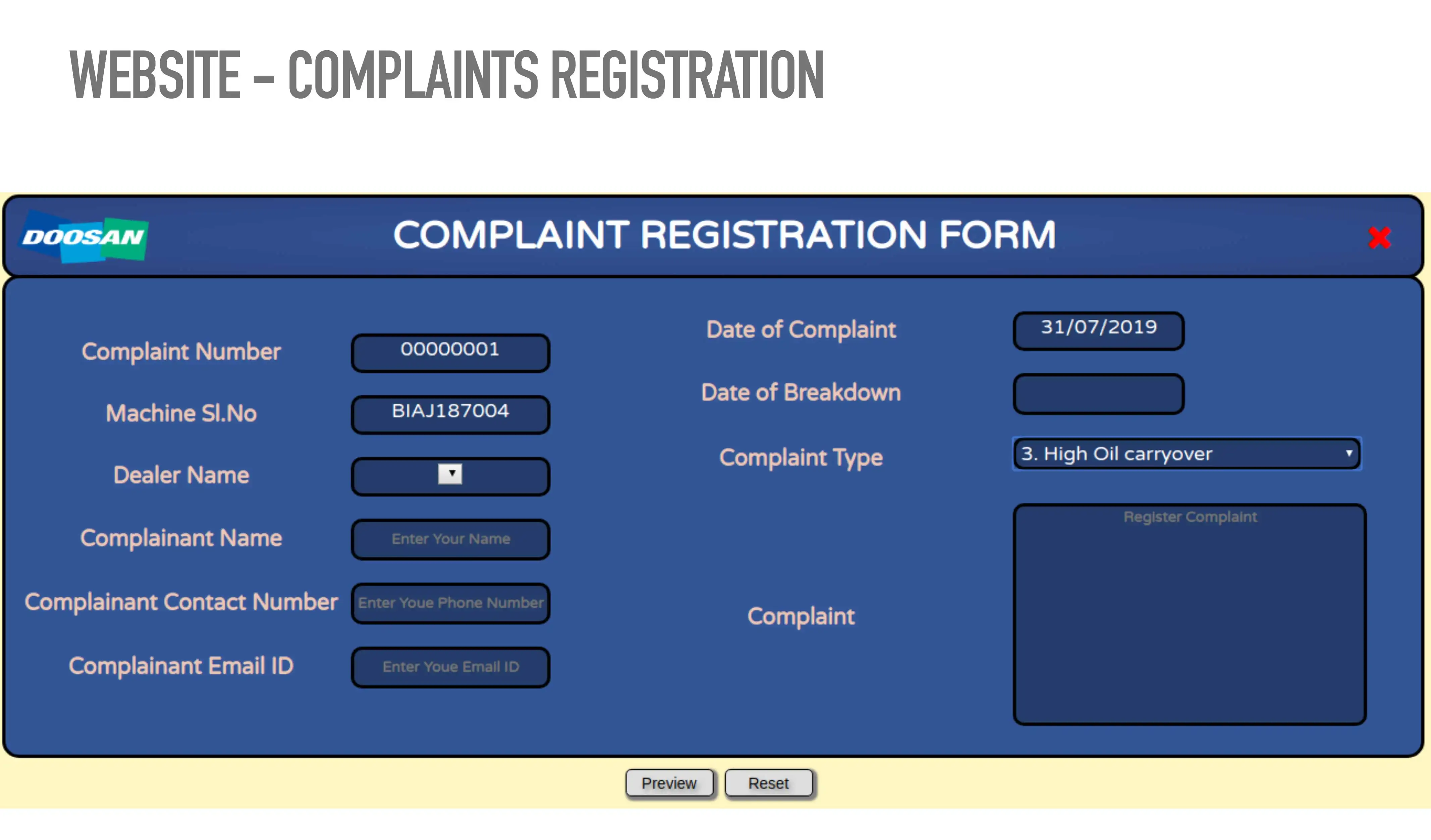

- Status & reminders notifications in SMS/Email for Maintenance to the people listed in website to receive SMS/Email

CAN BUS DATA ACQUISITION

- Air Discharge Pressure (psi)

- Regulator Pressure (psi)

- Air Discharge Temperature (Celsius)

- Oil Filter Switch

- Battery Voltage (V)

- Boost Pressure (psi)

- Machine Oil Pressure (psi)

- Coolant Temperature (Celsius)

- Hydraulic Oil Level

- Machine Trip Fuel (ltrs)

- Machine Total Fuel (ltrs)

- Machine Load (%)

- Machine Speed (rpm)

J1939 Protocol Implemented on CAN Bus to collect data from EURO4 Machines’ ECU

Display of 14 Parameters collected through J1939

REMOTE MONITORING & DASHBOARD

- Compressor Owner

- Dealer

- Service In-charge

- Company Head Quarters